The IELTS Task 1 Writing often presents candidates with various diagrams and processes, requiring them to describe these effectively in English. One such process you might encounter is the glass making process. This article provides a comprehensive guide on how to effectively describe this process for IELTS Task 1, ensuring you achieve a band 7 or higher.

Glass Manufacturing Process Illustration

Glass Manufacturing Process Illustration

Breaking Down the Glass Making Process

The glass making process typically involves several key stages:

-

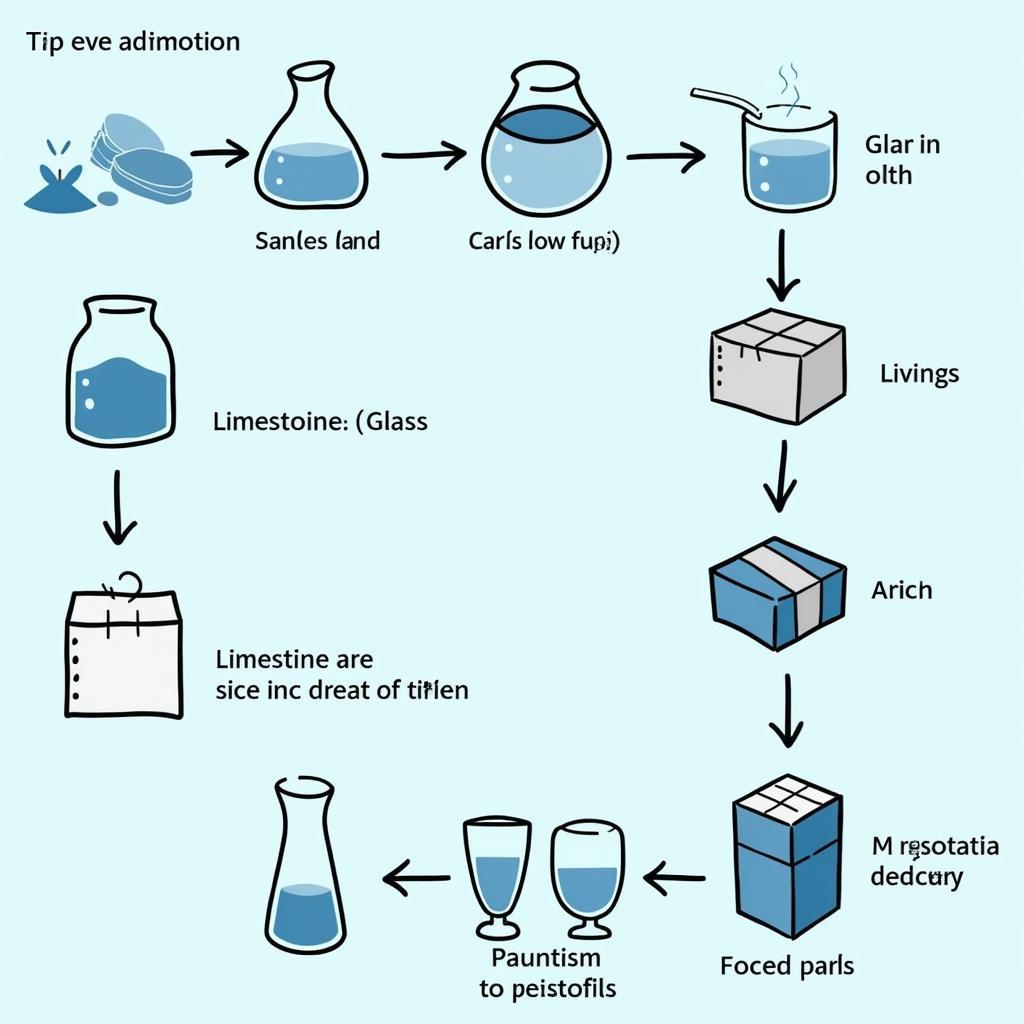

Raw Material Collection: The journey begins with gathering essential raw materials, primarily silica sand (silicon dioxide), soda ash (sodium carbonate), and limestone (calcium carbonate). These materials are carefully selected and measured to ensure the desired properties of the final glass product.

-

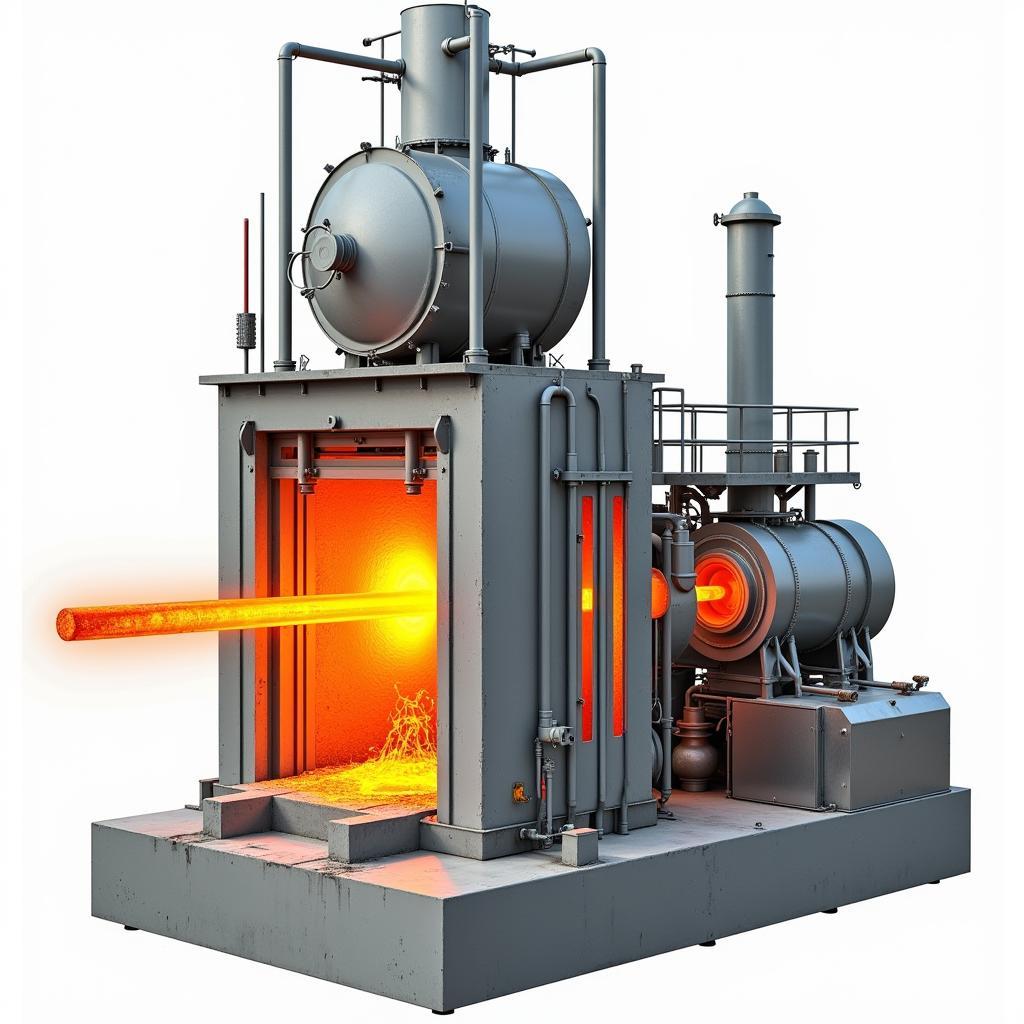

Melting and Refining: The collected raw materials are mixed in precise proportions and then fed into a furnace. Here, intense heat, often exceeding 1500 degrees Celsius, melts the mixture into a molten state. This molten mixture, known as “cullet,” undergoes a refining process to remove impurities and air bubbles, ensuring a clear and flawless glass.

Glass Melting Furnace Depiction

Glass Melting Furnace Depiction

-

Forming and Shaping: Once refined, the molten glass is ready to be shaped. This can be achieved through various methods, each resulting in different glass forms:

- Float Glass Process: Widely used for producing flat glass sheets, this method involves floating the molten glass on a bed of molten tin. The controlled environment ensures a smooth and uniform surface.

- Blowing: This traditional technique involves gathering molten glass on the end of a blowpipe and then blowing air into it to create hollow shapes like bottles and vases.

- Pressing: For producing lenses, dishes, and other shaped glass objects, molten glass is pressed into molds using mechanical force.

Various Glass Forming Techniques

Various Glass Forming Techniques

-

Annealing: After shaping, the glass undergoes a crucial heat treatment process called annealing. This controlled cooling process relieves internal stresses within the glass structure, preventing it from cracking or shattering under pressure.

-

Finishing: Finally, the annealed glass may undergo additional finishing processes depending on its intended use. These can include:

- Cutting and Grinding: To achieve specific dimensions and shapes.

- Polishing: To enhance clarity and smoothness.

- Coating: To add functionalities like UV protection or reflectivity.

Writing an Effective IELTS Task 1 Response

When describing the glass making process for IELTS Task 1, follow these tips:

- Paraphrase: Begin by paraphrasing the provided diagram title using synonyms like “manufacturing” or “production” instead of “making.”

- Overview: Provide a brief overview of the process, highlighting the main stages involved.

- Details: Describe each stage sequentially, using clear and concise language. Focus on the key actions and transformations occurring at each step.

- Linking Devices: Employ a variety of linking words and phrases (e.g., “Firstly,” “Subsequently,” “Moreover”) to ensure a smooth and coherent flow of information.

- Vocabulary: Utilize specific vocabulary related to materials, processes, and equipment involved in glass making.

- Grammar: Maintain grammatical accuracy throughout your writing, paying attention to verb tenses, subject-verb agreement, and article usage.

Practice Makes Perfect

Remember, consistent practice is key to success in IELTS Writing. Familiarize yourself with different types of process diagrams and practice describing them effectively within the time limit. By following these guidelines and practicing regularly, you’ll be well-prepared to confidently tackle any glass making process or similar diagram in your IELTS Task 1 Writing.